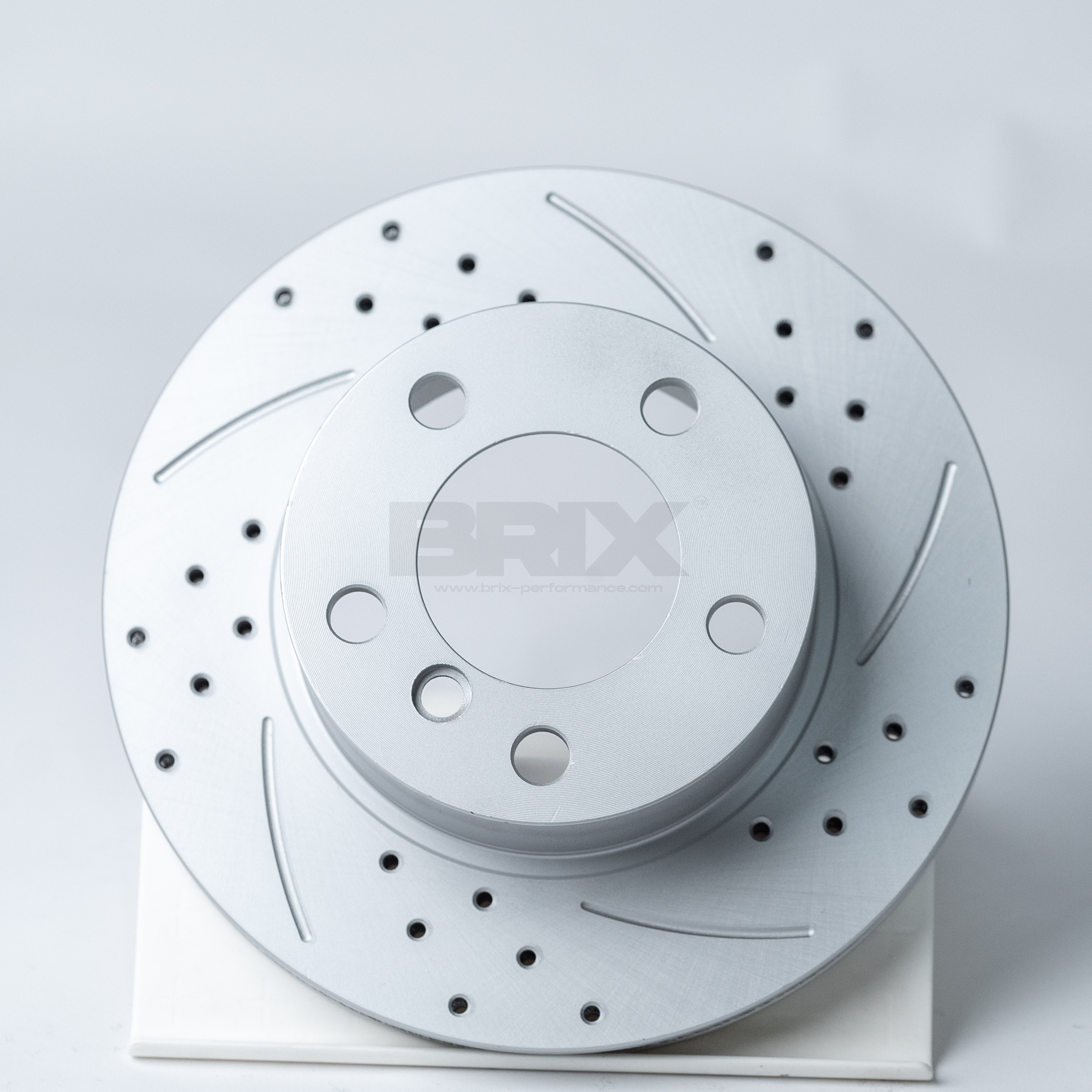

SOLIDCAST® - STREET SERIES

BRIX Performance Street Series is our high-performance street disc. Equipped with experience, knowledge, and data from our racing division for a performance rotor that suites day to day driving. Manufactured using BRIX SOLIDCAST® heat treatment and casting technique which enables the disc to cool evenly, achieving increased dimensional stability and reduced disc internal stress. Our products comply to TUV/ISO/TS16949 standards. BRIX Performance Street Series is a direct replacement to the factory equipped brake rotor with plug and play installation.

- Plug & Play

- SOLIDCAST® Heat Treated

- Monobloc

- Drilled & Curve Slotted

- High-Temp Coating

SOLIDCAST®

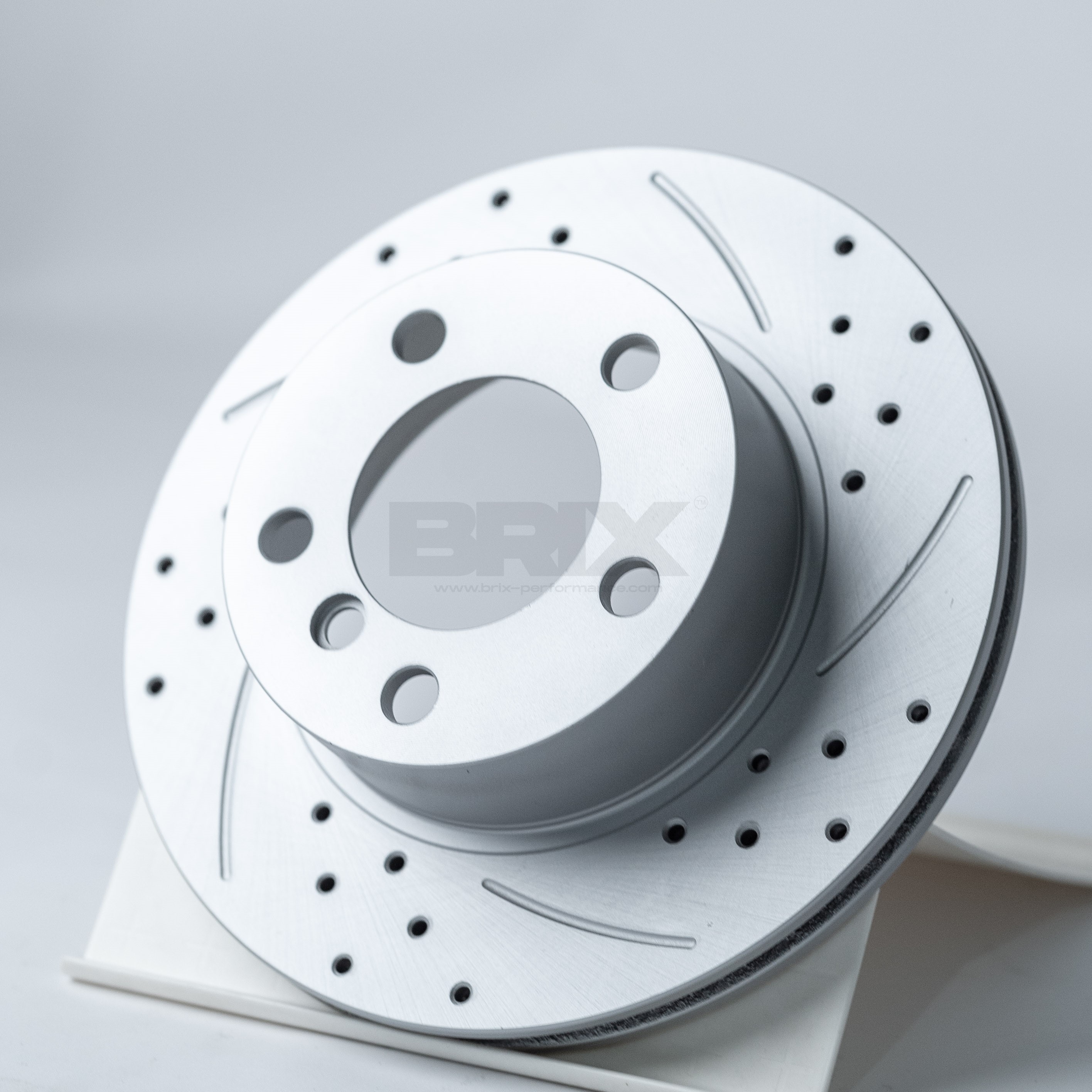

Heat-treatment can make or break a brake rotor. That is why BRIX Performance developed our own heat-treatment technique, which relieves internal stresses introduced into the rotor during production and machining. These processes makes the Street Series more resistant to warp and can sustain repeated high temperature use and lots of thermal cycling compared to OE discs, meaning reliable brakes whenever you need it thanks to the SOLIDCAST® technique.

The SOLIDCAST® technique, combined with our GS3000 cast iron blanks results in the perfect street rotor, with increased dimensional stability and slower wear rates even when using the more aggressive high metal content, high performance brake pads.

DRILLED AND SLOTTED? NO WORRIES!

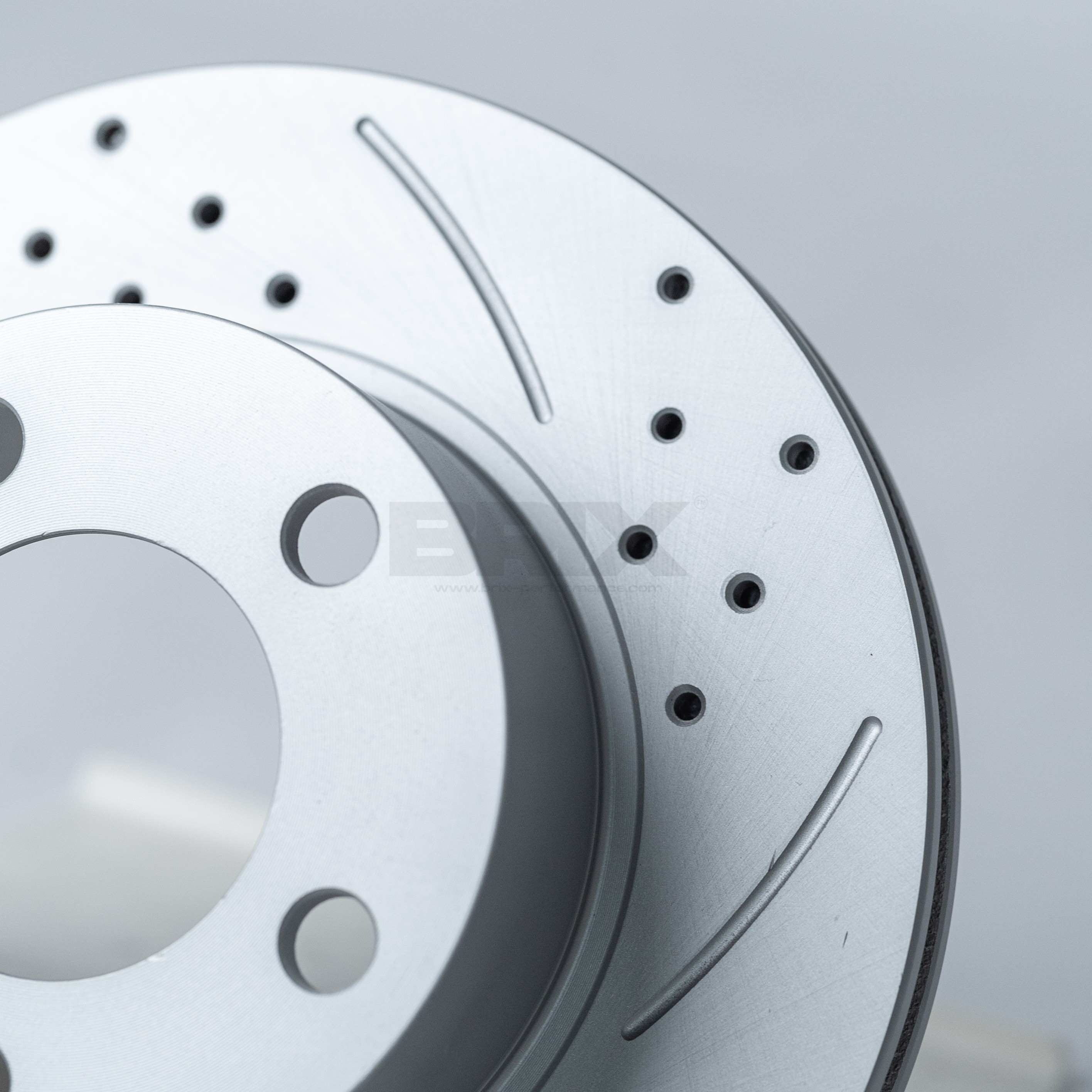

The Street Series is drilled and slotted, but it’s night and day when compared to the DIY solution of drilling OEM Brake Rotors for better looks or performance that introduces stresses and deformations on the rotor, which makes it prone to failure.

Our Street Series is specifically designed, engineered, and processed with the slots and holes in mind. The rotors are heat-treated and stress-relieved with our own SOLIDCAST® technique after machining, further reducing the risk of disc failure, and removing even the smallest internal stresses on the rotor surface after machining, meaning it resists warping and deformations better than an OE disc. The holes are drilled between the cooling channels, maintaining the structural integrity of the brake rotor.

The drilled and slotted rotor face aren’t there for the looks. It’s there to provide up to 20% increase in heat dissipation, an increase in overall braking power and better pedal feel compared to an OEM disc. The street series has a chamfered hole to further resist cracking, as it increases the surface area and reduce stresses on the holes, for reliable brakes that don’t break.

The drilled and slotted surface also provide biting points for the brake pad, resulting in higher braking performance, in expense for a slight increase in brake pad wear. This biting points will also reduce the pad glazing effect during repeated high temperature use, it results in a consistent brake pad performance. As the brake system temperature rises during usage, the drilled and slotted surface will provide plenty of escape routes for dust, gasses, or even water which compromises pad and rotor contact, ensuring a more consistent performance even in the most demanding conditions. Our drilled and slotted pattern is optimized for a more responsive and linear brake pedal feel, allowing drivers to feel confident with predictable, responsive brakes.

ANTI-CORROSION COATING

All of our Street Series Brake Rotor is equipped with high temperature anti-corrosion coating, it’s the silver finish you see when you open the box. As a brake rotor is exposed to the elements, this coating will help the rotor hub looking fresh and new for longer. Bear in mind that the brake pad will scrape the coating off the pad contact area.